Tyrolon-Schulnig GmbH – bottling efficiency

Tyrolon Hochfilzen

Driven by the ambition to constantly improve upon the maintenance of complex systems, Ludwig Schulnig founded Tyrolon-Schulnig GmbH in 1981.

The product portfolio developed from the production of sealants and moulded parts, to manufacturing mechanical seals and developing an alternative spare parts programme for the bottling industry. Over time, Tyrolon has developed into an innovative and reliable partner for the bottling industry with a broad product portfolio.

The early years

The company started its operations by processing fluoropolymer resins for the production of sealants and format parts in the “proverbial garage”, demonstrating a real pioneering mindset. Building upon the initial successes, the product portfolio was quickly expanded by manufacturing and servicing seals, especially mechanical seals.

Relocation to Hochfilzen

As the company became more successful, it outgrew the original production site, and Tyrolon invested in a new facility for production and administration and relocated the company to Hochfilzen. The production capacity has been continuously adapted in recent years to meet rising demand, and the production facility has been repeatedly enlarged

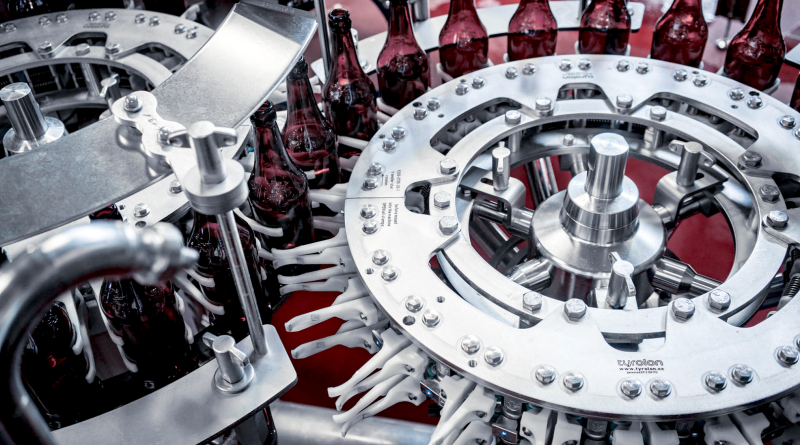

| High-tech solutions for the bottling industry | Smart High-End-Solutions Our products always embody perfection – our customers demand high-end solutions and innovative customised products. State-of-the-art machinery and error-free processes and procedures are a must in our production facility. Our production centre includes CNC machines with up to 7 axes for turning, drilling, milling and moulding, as well as CNC sinker EDM facilities and laser technology. We live and breathe innovation At Tyrolon, innovations and refining existing products are all in a day’s work. Many of our new developments, innovations and product improvements are patented. This includes the tyrolon Star, the tyrolon neckhandling aswell as compact gripper, linear guiding tulips and cleaning cups, the regeneration heads for refillable PET bottles or improved special holding tulips. There is a pronounced sense of motivation in our Research and Development unit, most notably on the continuous improvement of our products and solutions to provide significant added value to our customers. |

The tyrolon Star® The tyrolon Star® | Universal transport star tyrolon Star® is a universal transport star that enables the transport of bottles or containers of various shapes and sizes without having to adapt format sets, round blanks, or guides. Conventional systems call for complex format sets for each bottle format, resulting in time-consuming conversions. The tyrolon Star®, on the other hand, requires no further accessories, and it can remain on the premises for conversions. tyrolon Star® can handle bottles and containers in a range of 40 mm from the smallest to the largest diameter without conversions. |

tyrolon® Neck tyrolon® Neck | Innovatives Neckhandling Newly developed the tyrolon® neck clamp system is an ideal alternative to previous solutions. Clamps can be easily replaced with no need for additional modifications to the star. The compatible replacement kit contains the new plastic clamps, as well as the optimised switch cam, and is mounted on the existing retaining plate. |

Universal neck clamp for PET-Handling Universal neck clamp for PET-Handling | Perfect Solution Universal neck clamp from Tyrolon The new universal neck clamp is adaptable to all known machine brands in PET/neckhandling areas. Gentle gripping by magnet force prevents from neck damages and variably adapting to diameter – small differences are compensated easily. Diverse in use Different bottle sizes. Optimize your production with a powerful, efficient and low-maintenance solution. We would be happy to advise you on this. |